info@gunther.co.uk

Unlocking Efficiency: The Advantages of Using Multi-Couplings in the SMED Process

How Quick-Connect Technology Drives Faster, Safer Changeovers in Lean Manufacturing

In today’s competitive manufacturing landscape, time is money - and the faster a machine can switch from producing one part to another, the more agile and cost-effective a company becomes. That’s where SMED (Single-Minute Exchange of Die) shines. Developed by Shigeo Shingo, SMED is a lean manufacturing technique designed to drastically reduce setup times and increase production flexibility.

A critical component in optimising the SMED process is the use of multi-couplings. Though often overlooked, these devices can make a substantial difference in reducing downtime and complexity during changeovers.

What Are Multi-Couplings?

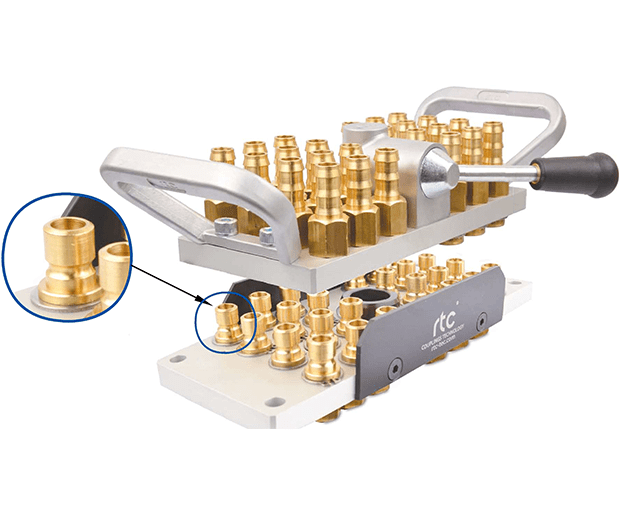

Multi-couplings are connection systems that allow simultaneous and secure connection/disconnection of multiple fluid, electrical, or pneumatic lines. Instead of connecting each hose, wire, or pipe one at a time, a multi-coupling enables the operator to connect them all in a single motion.

How Multi-Couplings Enhance the SMED Process

1. Significantly Reduced Setup Time

One of the primary goals of SMED is to convert internal setup tasks (which require the machine to be stopped) into external tasks (which can be done while the machine runs), and to streamline or eliminate remaining steps. Multi-couplings help achieve this by bundling connections, so instead of taking 15 minutes to hook up several lines, the operator can do it in seconds.

2. Fewer Errors During Changeover

Traditional changeovers often involve multiple hoses or connectors, which can be plugged into the wrong port, leading to downtime, defective parts, or safety hazards. Multi-couplings eliminate human error by designing the system to only connect one way, reducing the chance of misconnection.

3. Improved Operator Safety

Dealing with pressurized lines or electrical connections always carries some risk. Multi-couplings automate the connection process, reducing direct human interaction with potentially hazardous systems. Some systems also include safety interlocks to prevent disconnection under pressure.

4. Higher Repeatability and Standardisation

Consistency is key in lean manufacturing. With multi-couplings, connections are always made the same way, regardless of who is doing the setup. This reduces variability in changeover performance and supports standard work - another core lean principle.

5. Cleaner Work Environment

Leaky hoses or improperly sealed connections can cause spills or contamination. Multi-couplings are designed with automatic shut-off valves, which minimise fluid loss and keep the work area clean, supporting 5S and other workplace organisation goals.

Real-World Application Example

Imagine a plastic injection moulding company using water, air, and hydraulic lines for each mould. With conventional connectors, an operator might spend 10–15 minutes carefully disconnecting and reconnecting these lines. With a properly designed multi-coupling system, the same task could take less than a minute - with virtually zero risk of misconnection or leakage.

Conclusion

If you're implementing SMED in your facility, multi-couplings are a low-hanging fruit that can yield high-impact results. They streamline operations, reduce human error, and support faster, safer, and more consistent machine setups. As with all lean tools, the goal is not just speed - it’s creating a more efficient, reliable, and flexible production system.

What our clients say

We’ve used Gunther Hot Runner Systems, OptiMach special machining, and Knarr collapsible cores via Gunther UK for a number of years. The quality is always exceptional and the service is responsive and reliable.

New Tooling Manager

Major UK OEM

Gunther’s demonstrated technical knowledge allow us to confidently provide working, robust moulds that produce consistent parts. Delivering a quality product and incredible support are more important today than ever before, Gunther never fails to deliver this, which in turn helps us to provide the same service to our customers. I can’t recommend them enough.

UK Toolmaker/moulder

We’ve been working with Gunther UK since 1988, and they’ve never let us down. The combination of personal service, trustworthy advice, and consistently high-quality hot runner systems and mould components has cemented our relationship over three decades. They feel less like a supplier and more like a partner we can rely on.

Gary Statham

Neptune Injection

Sign up for our newsletter

Newsletter